THE PROJECT

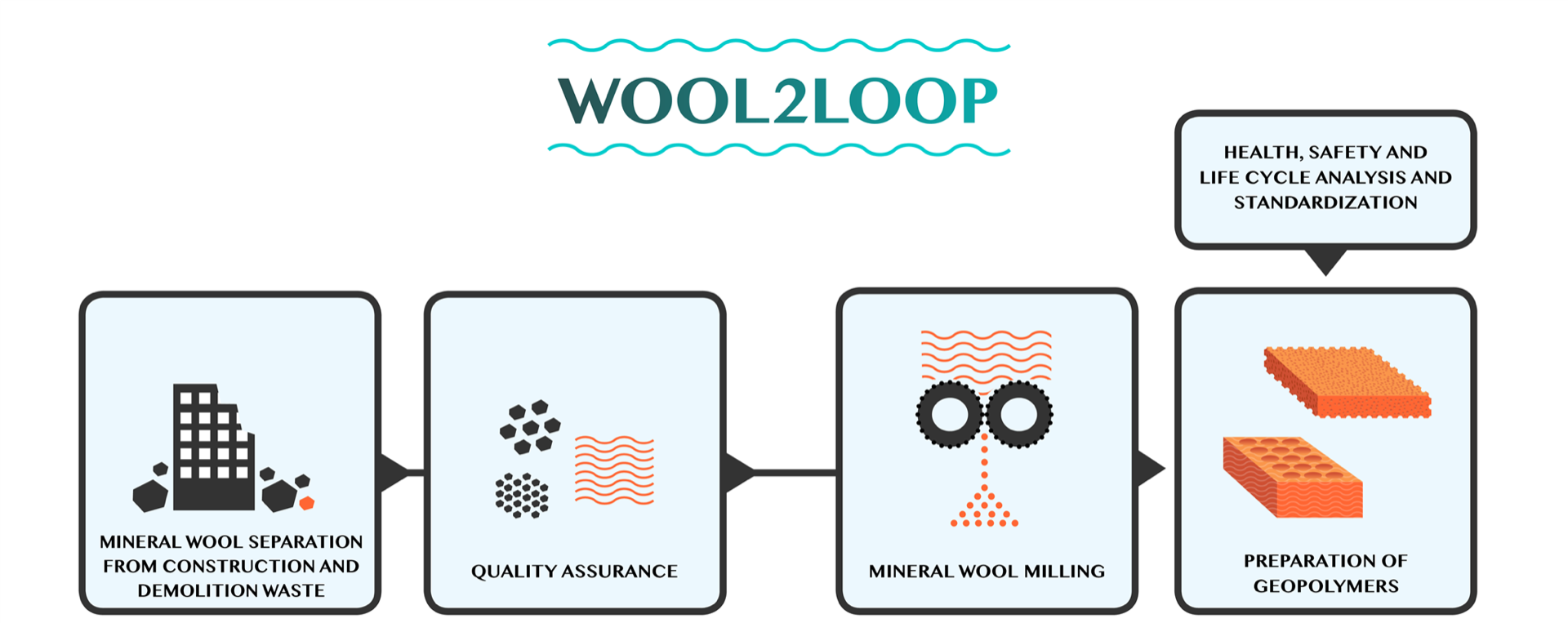

WOOL2LOOP project outline

The overall objective of the WOOL2LOOP project is to divert mineral wool waste from landfilling and enhance its utilisation in novel products. At the same time, the access to sustainable, alternative and non-conventional raw materials for the construction industry is secured in the future.

Figure: WOOL2LOOP project outline.

Specific objectives

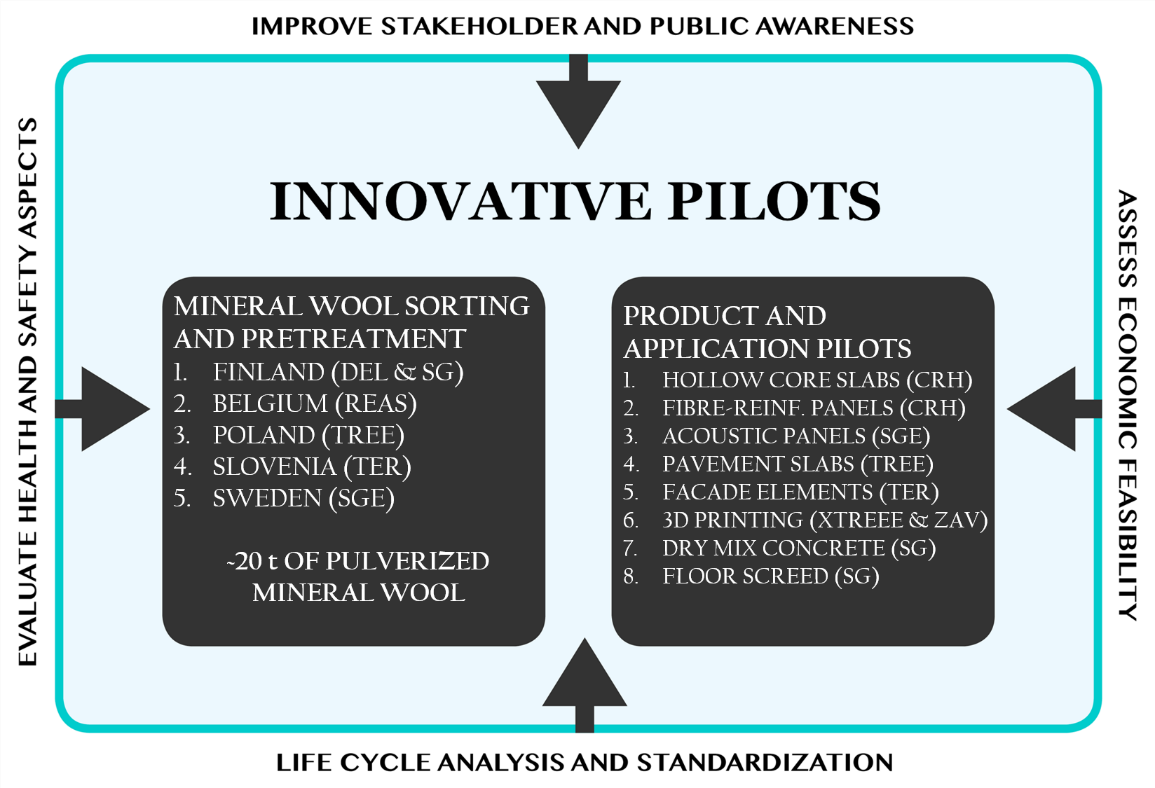

The specific objectives of the WOOL2LOOP project are:

1. To enable consistent quality mineral wool raw material from construction and demolition waste.

2. Use novel on-site analytical methods for the analysis of mineral wool waste.

3. Develop milling and pre-treatment technology for mineral wool waste.

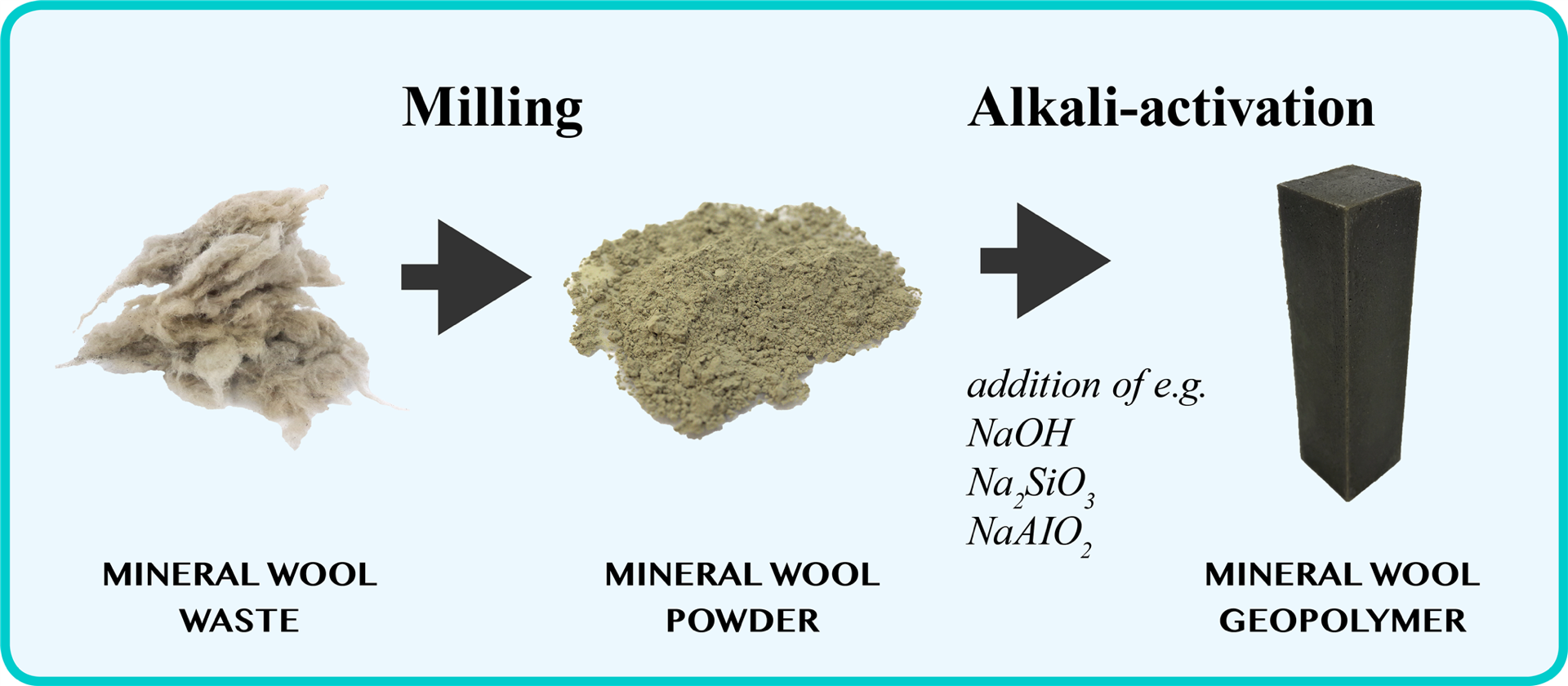

4. Demonstrate the manufacturing of new products using the alkali-activation technology. Alkali-activation (or geopolymerisation) is becoming more widely accepted method to prepare low carbon dioxide binder, other products and materials from several industrial by-products, one promising being the mineral wool waste. Mineral wool geopolymer concrete is estimated to produce approximately 80 % less CO2 emissions compared to regular concrete. The manufacturing of the different products will be demonstrated: fiber-reinforced panels, acoustic panels, pavement slabs, façade elements, 3D-printing equipment optimised for mineral wool geopolymers, dry mix concrete, and floor screed. Also, the recyclability of alkali-activated materials as an aggregate is verified.

5. Ensure the health, safety and environmental performance and requirements thorough the value chain.

6. Evaluate the circular economic feasibility of the developed value chain.

7. Communicate results and engage with the expectations about the future utilization prospects of mineral wool waste and to create the awareness among external stakeholders and the general public across the EU.

Figure: Specific objectives of WOOL2LOOP.

Concept and methodology

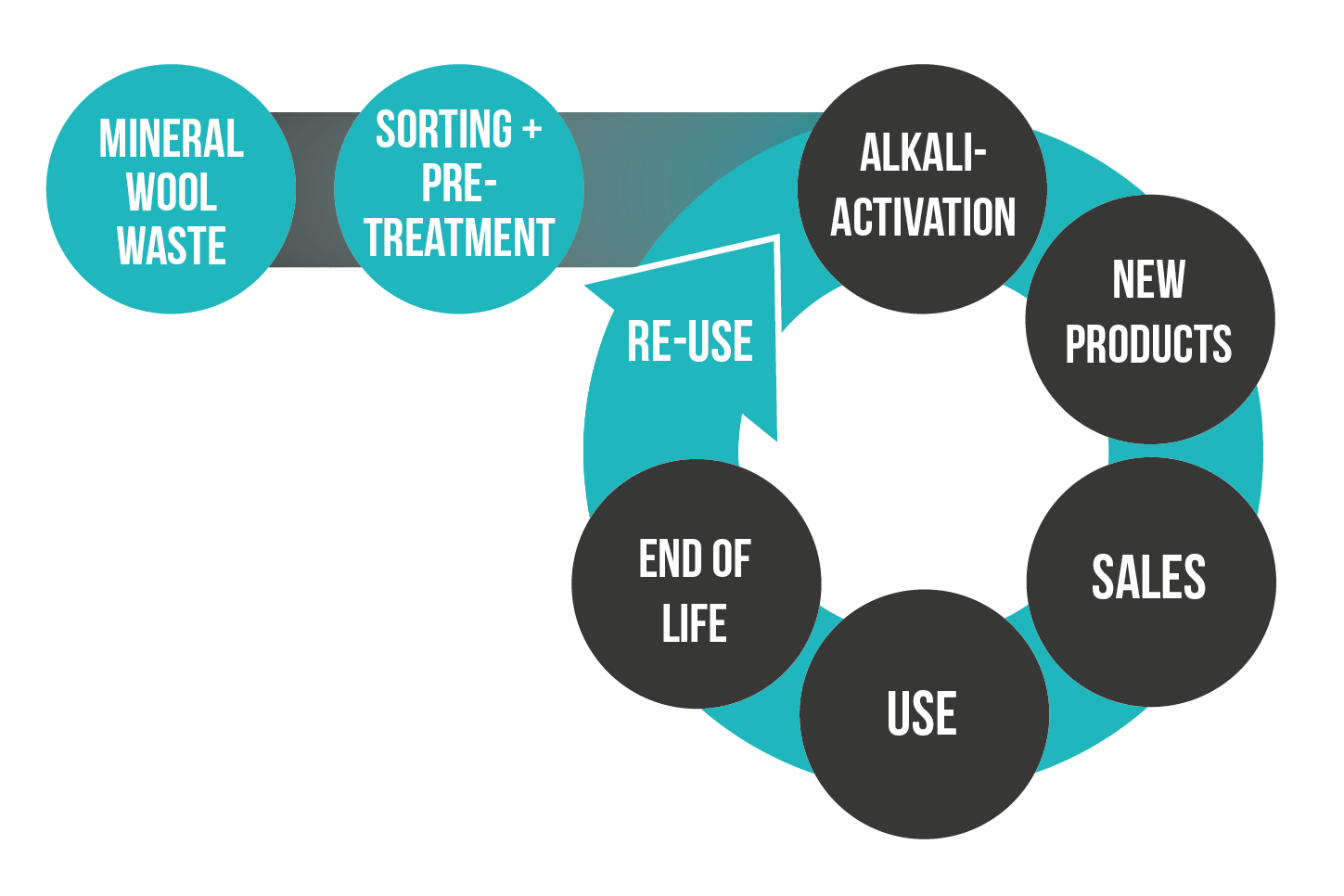

The WOOL2LOOP overall concept is to separate high quality mineral wool waste from construction and demolition waste, mill it (together with other possible pre-treatments), utilize it as raw material in alkali-activation, and re-use it after the end of life of products.

The first step of the overall concept is to find the best approach for obtaining consistent quality mineral wool from construction and demolition waste. The approaches that will be compared different smart demolition approaches.

For quality control on the demolition site or at the transfer station, novel on-site analysis will be employed. Aim is to identify different mineral wool types (glass, stone, and slag wools) and wools from different decades - therefore it is used for quality assurance. For instance, the aluminum content of stone wools increased in 1997 due to the requirement for solubility in respiratory system if inhaled (biosolubility). The reactive aluminum concentration is important as it is one of the main elements reacting in alkali activation. Earlier research has pointed out serious difficulties in the quality management of post-consumer mineral wool wastes, which can be largely solved by the on-site analysis.

After sorting, mineral wool is pre-treated using suitable milling to obtain compacted material. This will remove problems related to the low density and thus allows cost-efficient logistics. Pulverisation is also required for further processing and the conversion of mineral wool into new products using alkali-activation technology.

Several concrete or ceramic-like materials and products can be formed based on the adjustment of mix design. In the WOOL2LOOP project, the products that will be demonstrated are acoustic panels, dry mix concrete, floor screed, pavement slabs, façade elements, 3D printing equipment for mineral wool geopolymers, and fiber-reinforced panels. These products are supplied for the construction industry end users for a service life that is expected to be at least similar to concrete (~50 years). Safety aspects during manufacturing and product lifetime are assessed in the WOOL2LOOP project by conducting extensive chemical and microbial analysis. Once the products face their end-of-life, they can be recycled again as aggregate. Recycling is also demonstrated in the project in laboratory-scale. Thus, the material loop is closed.

©WOOL2LOOP 2020